Accepting command of the Continental Army in 1775, General George Washington requested an inventory of gunpowder stores. The report of 90 barrels left him speechless. His mood brightened a bit in March of ‘76 when a Congressional Committee of Secret Correspondence shooed Connecticut merchant Silas Deane to France, with an appeal to American sympathizer Pierre-Augustin Caron de Beaumarchais, confidant to Louis XVI. Result: Roderique Hortalez & Co., a group organized to smuggle Dutch, French and Spanish arms and other supplies to the colonies. These included gunpowder from Antoine Lavoisier, whose factory produced powder for the French government

Lavoisier had earned his credentials by refining the ratios of black powder’s ingredients. He declared his powder, of 75 percent saltpeter and 12.5 percent each of charcoal and sulfur, “the best in Europe.” But to American rebels, availability mattered as much as quality. By the end of 1777, France had shipped two million pounds to the Continental Army. This powder and 60,000 donated infantry arms (roughly one for every soldier) helped secure a pivotal victory at Saratoga in October that year.

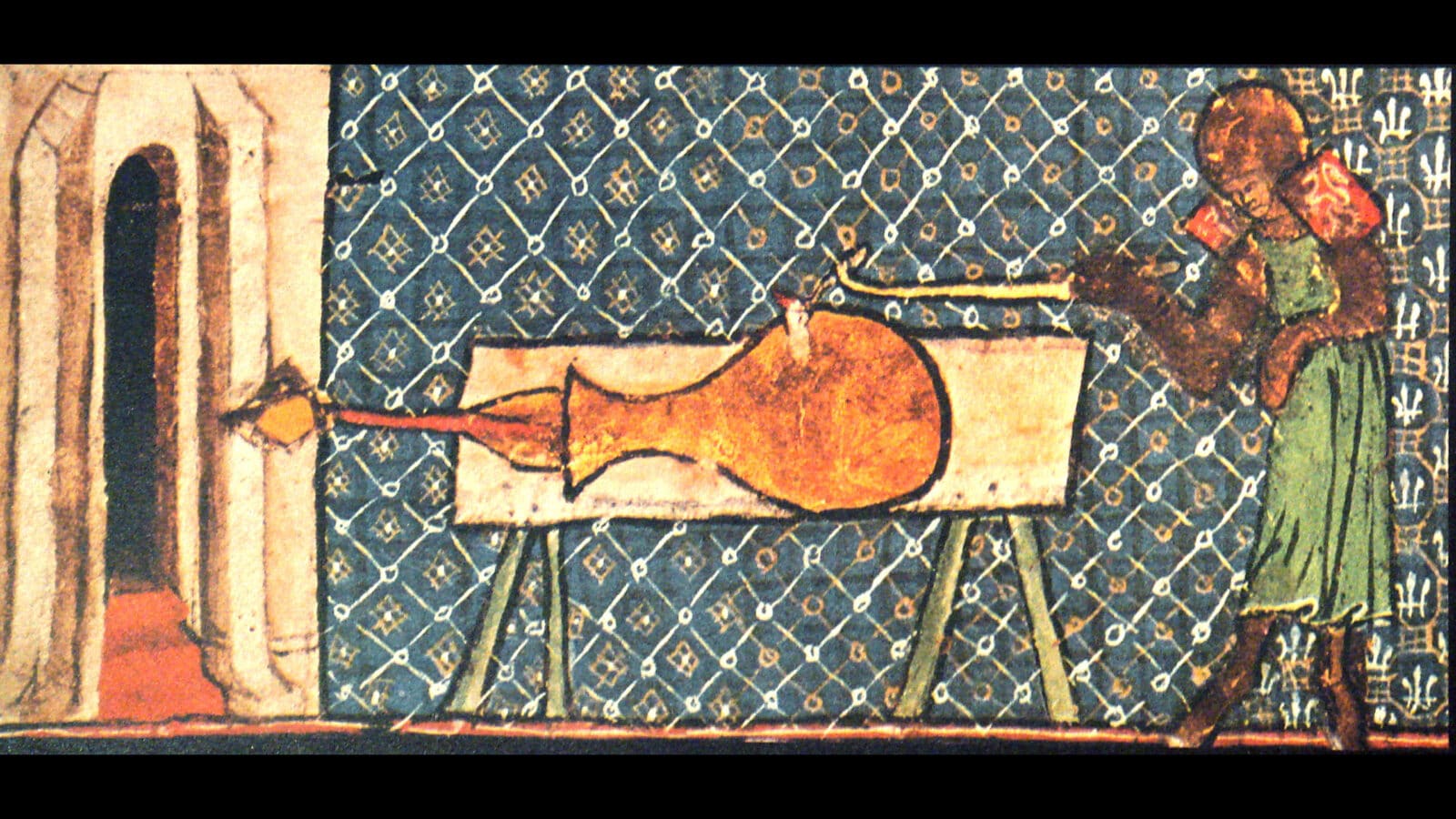

While crude explosives date to ancient China, the English Friar Roger Bacon is credited with the first description of gunpowder in 1249. Rudimentary firearms soon followed. From the 14th century to the late 19th century, black powder furnished the high-pressure gas that hurled all manner of projectiles, from rocks to jacketed bullets, at animals and adversaries. Its varied blends of fuel and oxidants all contained saltpeter (potassium nitrate), charcoal and sulfur. In 1846, an Italian, Ascanio Subrero, discovered nitroglycerine. A clear, oxygen-rich solution of nitric and sulfuric acids plus glycerin, “nitro” could quickly rearrange itself into stable gases. No need for spark; a bump would set it off. In 1863, Swedish chemist Alfred Nobel and his father, Emmanuel Nobel, learned how to put this volatile, explosive compound in cans. Still, it punished inattention. In 1875, after it leveled Nobel’s German factory, Alfred developed the relatively docile Dynamite.

By then, the Swiss chemist Christian Schoenbein had discovered that cotton treated with sulfuric and nitric acids burned so fast, it turned to ash without igniting its bed of black powder! Efforts to throttle it and carelessness proved costly. John Hall’s guncotton plant in Faversham, England blew up. Stateside, German immigrant Carl Dittmar lost his New Sporting Powder factory to an explosion that erased much of Binghampton, New York. Some accidents tallied more victims than survivors.

In the 1890s black powder gave way to nitrocellulose-based smokeless. Single-base propellants contained no nitroglycerin. England’s cordite, named for its spaghetti-like strands, was initially a double-base powder, with guncotton, nitroglycerin, petroleum jelly and acetone. Addition of nitroguanidine in the 1930s made it a “triple-base.”

Long ago, DuPont powder guru Larry Werner assured me that double-base powders have more energy per grain than single-base. “But to see that edge, you need about 10 percent nitro.” He noted that double-base spherical powders are especially useful in cases of limited capacity. “Their drawback is residue; they don’t burn as cleanly as single-base.”

Diphenylamine or a similar stabilizer is present in nearly all smokeless powders to extend shelf life. Some have flame retardant to reduce muzzle flash. Another additive — graphite — gives powder its gray color, though that coating’s main job is to ward off static electricity as grains rub against each other.

Physically, powder comprises grains, as does sand. Powder charges are given in grain weight — entirely different. There are 437 ½ grains per ounce, 7,000 grains per pound, the unit dating to the Bronze Age and its wheat. Black powder for muzzle-loading rifles is measured by bulk (a cup is a bulk measure). But an adjustable powder measure is pre-set by the shooter to hold a given weight of powder when filled.

Pyrodex, Hodgdon’s black powder substitute, is only about 70 percent as heavy as black. Both are measured in bulk 1:1. Convenient pellets in specific equivalents make loading easy. Two 30-grain pellets, for instance, comprise a 60-grain charge. Ditto for the Triple Seven substitute and its Firestar pellets.

A Matter of Interpretation

Powder designations are usually meaningful but often beg interpretation. Early DuPont smokeless powders came in cans marked “MR” (military rifle). Improvements brought the IMR series in the 1920s as four-digit DuPont numbers replaced two-digit, beginning with 4198. In 1934, DuPont introduced IMR 4227. IMR 4895 would fuel the .30-06 in M1 Garand infantry rifles. IMR 4831 for 20mm cannons would prove a top choice for medium-bore magnum rifle cartridges of the 1950s and ‘60s.

Aware that huge quantities of military powders had been dumped at sea after WWI, Brewster E. Hodgdon had a better idea. After his U.S. Navy service in the ‘40s, he set about buying up surplus powder to supply handloaders. First step: borrowing against his life insurance to sock 25 tons of IMR 4895 away in a salvaged boxcar on a rented field. Customers who responded to his modest ad in American Rifleman got 150 pounds for $30!

Sons Bob and J.B. crated it and took it to REA and Merriam Frisco terminals on the Kansas City rim in a 1940 Ford. Brisk demand birthed the Hodgdon Powder Co. in 1966. Magazines appeared on 160 acres west of its headquarters in Overland Park, Kansas. They’d become a staging area for four million pounds of propellant!

His bonanza in surplus powders almost gone by 1959, Bruce turned to military sources offshore, one of them having supplied British forces from a plant in Scotland. He also tapped commercial powder houses stateside — notably the Olin Corp., which furnished a line of spherical powders pioneered by John Olin in 1933. “Ball Powder,” by the way, is a trademarked moniker owned by Winchester, then an Olin asset. Spherical powders from other sources are best called … well, spherical.

Now Hodgdon sells 13 Winchester canister powders under a licensing agreement. While DuPont did not release its extruded (“stick”) powders to Hodgdon during Bruce’s search for commercial partners, it would sell Hodgdon its business in 2003, with a stable that now comprises 15 IMR powders. Hodgdon, meanwhile, was growing its rifle, pistol and shotgun series to offer handloaders 35 options. Its Extreme line, led by Varget in 1996, performs across a wide temperature range. Hodgdon also sells Superformance and LEVERevolution powders, which sprang from Hornady’s work with specific cartridge classes.

Having welcomed ADI (Australian Defense Industries) propellants into its fold, Hodgdon added 22 more from Accurate Arms. In 2020, Ramshot joined, with a dozen offerings — plus Blackhorn 209 to complement Hodgdon’s Pyrodex and Triple Seven for muzzle-loaders.

Hodgdon once distributed Finland-bred Vihtavuori propellants. This brand catalogs more than 20 superb single- and double-base powders, now marketed by Capstone Precision Group. Another popular powder brand stateside is Alliant, whose roots run to Laflin & Rand in 1872. DuPont’s divestiture in 1912 brought about the formation of Hercules Powder Co., then Alliant, now part of Vista. With 21 propellants for shotguns and handguns, Alliant lists 19 (in Reloder and Power Pro lines) for rifles.

Hodgdon manufactures no powder. Instead, its chemists develop products with the staffs at powder factories like St. Mark’s. With over 120 propellants in its group of companies, the business Bruce Hodgdon started with a loan on his life insurance and a boxcar of surplus propellants on a rented pasture accounts for about 70 percent of gunpowder sold to U.S. consumers!

Reading the Tea Leaves

Apowder’s label may say nothing useful about its behavior in any given cartridge. After a career at Hodgdon, Ron Reiber told me Bruce renamed one powder because in his pet .22-250 “he discovered 38 grains drove 50-grain bullets at 3,800 fps. So WC852 is now H380. But if you’re not shooting a .22-250, H380 is still a versatile powder!”

Burn rate is charted in “closed bomb” tests. Ignited in a chamber of known volume, each powder yields a distinctive pressure curve. Larry Werner, whose work at DuPont began in the ‘50s, told me IMR powders were given Relative Quickness values. IMR 4350’s RQ of 100 shows it’s slower than IMR 3031, with an RQ of 135. IMR 4227 is fast, with an RQ of 180. Fast-burning propellants best serve small, wide-mouthed cases and short, light bullets. Think 9mm Luger. Its case capacity is modest, its base generous for the bullet’s small bearing surface. The bullet imposes little resistance at launch; a short barrel dumps pressure quickly. Slow powders excel behind long, heavy bullets. Instead of a slap, they give a muscular shove to overcome substantial mass and bore friction. Think 7mm Magnum. In gas-driven self-loading rifles, burn rates and pressure curves must ensure proper thrust at the barrel port.

Grain shape affects gas release as powder burns. Grains of flake and spherical powders shrink as they’re consumed; they burn regressively. Extruded powders are tubes (some grains have multiple tubes). Flame reduces outside area as it increases inside diameter. Grains whose total surface grows more than it shrinks are said to burn progressively. They extend thrust down long barrels. Spherical powders compete in this arena too, additives replacing grain structure to throttle gas release. Chris Hodgdon pointed out that “extruded powders are usually more consistent across temperature ranges than are spherical powders.”

Handloaders have debated differences in burn rate between IMR and Hodgdon propellants of the same number — 4831 for instance. Slight blending differences show up in load data. “When not specified, in data, assume the powder is IMR,” Chris advised. With charges of 70 to 80 grains in magnum hulls, I’ve found IMR 4831 a tad faster than H4831. But IMR 4227 and H4227 are essentially identical.

Gunpowder can stay potent for decades in its original capped container in a cool, dry place. Keep it above freezing. Old powder with red dust is deteriorating. Flush it down the drain.

While compressing a powder column with the bullet causes no harm, crushing grains by jamming a bullet deep into a tall charge can affect burn rate and pressures. The press of the powder can even cause bullet creep in the rifle’s magazine during recoil. Spherical powders, like marbles, don’t compress well.

Ideally, a powder column should comfortably fill a case. Dead space allows powder to change its position and perhaps its behavior. Reduced charges of slow powders in big cases have delivered pressure spikes. These may be caused by primer flame skating across the powder surface, igniting both ends of the charge. The burn then collides in a violent finish. Inert filler makes sense in reduced loads.

Powder leaves evidence of its action. Beware signs of high pressure: difficult extraction, flattened primers, bright ejector marks. Other signals can mislead. Muzzle flash may not mean there was too much powder; in fact, it’s more common with low-pressure loads and slow powders. Blackened case necks tell of pressures too mild to seal case necks against the chamber. Tracking velocities, a chronograph reflects pressures and shows when increasing charges reach a “performance plateau.”

Conclusion

Whichever powder you use, or how much of it, only about 30 percent of its energy will shove the bullet. About that amount is lost as heat inside the case and barrel, and nearly 40 percent leaves as useless exhaust! Even after 13 centuries of improvements!

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in!

Join the Discussion

Featured in this article

Read the full article here